No matter where you live, the temperatures will drop at least somewhat during the winter, and the difference can be more severe in some areas than in others. If you sell a product across the country, this means that you have to take into account the below-freezing temperatures of winter in the northern portions of North America. While your packaging may do fine at room temperature or even a bit above freezing, you need to take the time to confirm it can handle sub-zero temperatures before winter arrives. This way, you will be able to rest assured that your product will arrive at its destination in one piece without any damage.

Consider Packaging Materials

The first step to preparing your packaging for winter is considering what packing materials you use. Most materials do fine up to a certain point, but not everything will be able to survive temperatures far below zero, whether you are looking at degrees in Fahrenheit or Celsius. Cardboard is the most commonly used material for product packaging, and the good news is that it will typically be OK. However, you will want to keep the cardboard at a minimum of minus-60 degrees Fahrenheit (minus-51 Celsius). At this point, it will start to experience some damage. If you use more expensive wood packaging, then this won’t be an issue, although plywood does get brittle.

Pay Attention to Adhesives and Cushioning

In addition to the cardboard or other material that forms the main component of your packaging, you need to think about how it is sealed and what you put inside for cushioning. Certain adhesives become less effective at colder temperatures. Be sure your packaging is put together with glue or tape that is rated for winter weather. Lower temperature ratings are better since you never know how long your product will be sitting in a nonheated truck.

You also need to think about the other materials you put inside the packaging. If you don’t want the product to move around too much, you may opt for cushioning foam or Styrofoam. While Styrofoam isn’t great for the planet, it is excellent for winter weather. Even if it is exposed to extreme cold, it should still function normally. Cushioning foam that is made from polyurethane will stay flexible even once you reach minus-60 Fahrenheit while polyethylene foam is likely to hold up but has a greater risk of damage. Ideally, the cushioning will also insulate the product somewhat so it isn’t damaged by the cold.

Test It Out

If you have any doubts about whether your packaging can survive transportation during the winter months, consider testing it out. Take your existing packaging and put it in a freezer with the temperature turned down for a while or another cold area. Afterward, put it through some tests, such as tossing it around as it would be in the shipping truck or in the store. If you notice any issues, you will have the chance to fix it.

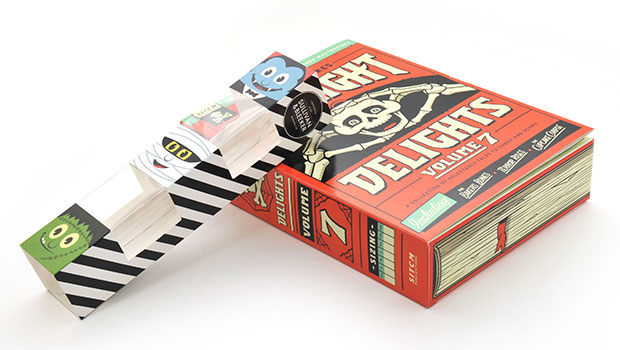

Don’t Forget About Winter-Themed Designs

Preparing your packaging for winter isn’t just about making sure it can withstand the cold temperatures. You can also take advantage of this time of year to create one-of-a-kind packaging designs that appeal to customers. Consider adding some snowflakes or other winter-themed designs to the packaging to help it stand out and appeal to consumers.