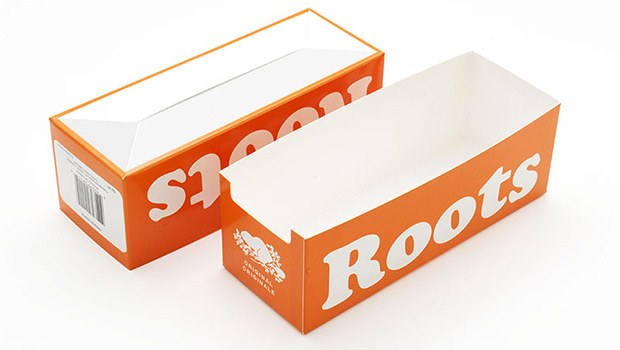

Box Style

BODY: Once upon a time, a box was a box. That is certainly no longer the case. Take a look around the next time you are in a big name store. You’ll likely see a huge assortment of box styles. Some are created with built-in display functions while others turn into a tray (these often hold smaller boxes on the shelves), while a gable box comes with a handle. In other words, there are tons of box styles, and after we talk to you, we will be able to recommend the perfect style for your needs.

Dieline

BODY: This is a common term in the design industry, although it’s not often a word used outside of designing. A dieline is basically a template or pattern that lays out the proper design. Dielines allow the designer to determine the proper size and shape of what will ultimately be the final product.

CAD Samples

BODY:CAD stands for “Computer-Aided Design”. CAD is a major tool used in the design of custom packaging because it allows the designer and the customer to speak the same language in terms of expectations. What will the package look like? Where will it open and close? What shape will it be? By utilizing the assistance of computers, you will be able to see a 2-D rendering of what your packaging will look life in real life when the process is complete. CAD samples can also allow you to have a box in the design that you ordered so you can test out its usefulness with regard to your product or company.

Offset Printing

BODY: This is a process that involves the desired image to be created on a plate, which is then covered in ink, which goes to a rubber blanket. From there, the image finds itself onto the desired surface. While the portion of the plate that is meant to stamp the image onto the final surface, the part of that product that is meant to stay clean of printing attracts a water solution, which keeps the ink from finding its way onto areas that it’s not supposed to be on.

Prepress Processes

BODY: While some companies outsource the part of the process that involves typesetting (or, basically, determining the font that will work best for your project), markups and proofing (making a sample of your project), manufacturing of plates, selecting the right paper, and everything that goes into the process prior to the commencement of production, we keep all of this right here in-house.

UV Coating

BODY: Obviously, one of the goals of creating your custom packaging is to get noticed by consumers that have tons of options to choose from. Glossy UV coating not only makes the packaging shiny and appealing to the eye, but it also serves as a rub-resistant material that helps to protect the surface of the packaging. Satin UV coating offers a contrasting flatter finish to packaging. When used together, these two products tend to create packaging that stands out to consumers far above the other options that are typically available on the shelves.

If you are ready to get started with your own custom packaging design, or if you have questions for us,contact a member of our team at SoOPAK today!