With rising costs on everything, companies are looking for ways to cut costs and boost profits. You can likely find some savings hidden in your product packaging costs if you know where to look. Keep the following tips in mind and find ways to boost your bottom line.

Reconsider Your Packaging Container

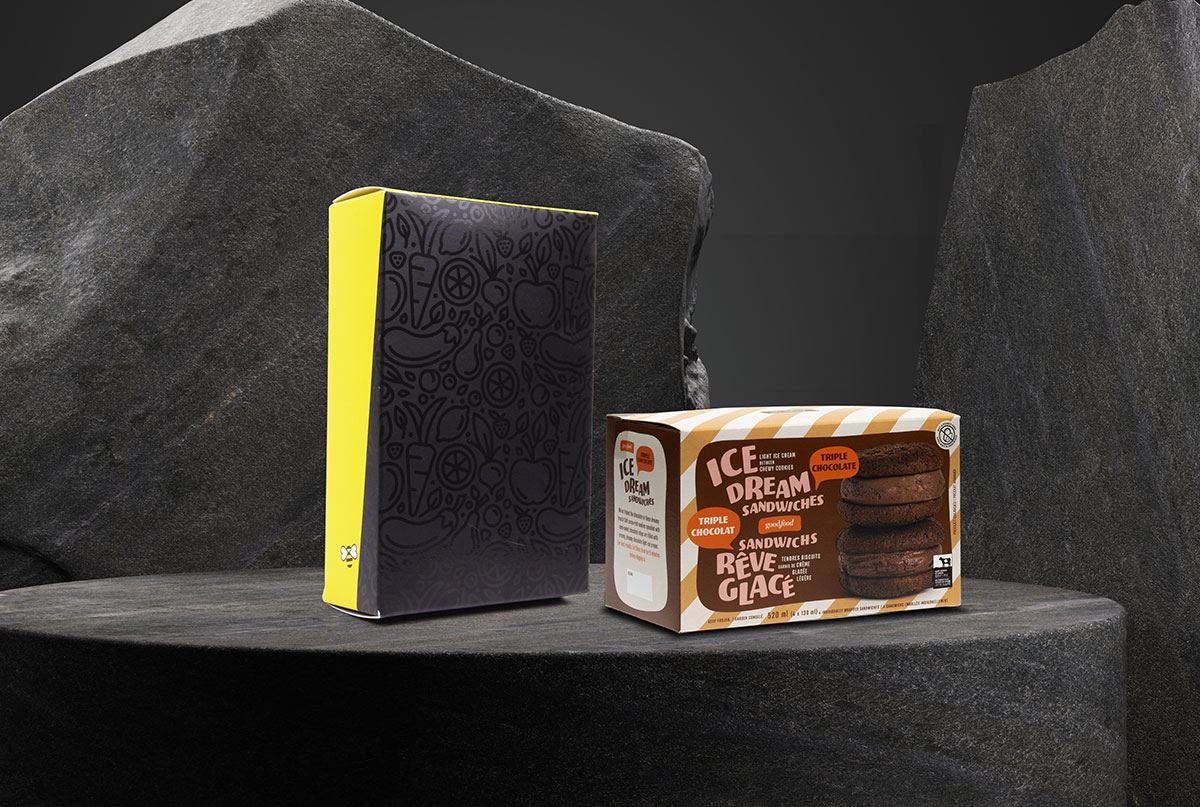

There is a long list of potential types of product packaging to choose from. Bottles, cans, boxes, pouches, and more all exist. Don’t keep using the same material just because it’s what you’ve always done. Take the time to see if you could save money by opting for a different material.

Just be sure not to just switch materials without thinking it through. Will the new material protect your product? How will it sit on shelves? Will you have to redesign anything else, such as your processing equipment or shipping methods? Account for everything before making a major change.

Consider Thinner Materials (Down Gauge)

If your current material is the best one for your product, consider whether you could down gauge. This refers to using less of it, so the packaging is thinner. Less material reduces the cost per package.

But the caveat here is to ensure the material is still thick enough. If it can’t adequately protect your product, you will lose more money than you save thanks to damaged products. Even damaged packaging can lead to a similar concern.

Choose a Size and Shape That Better Fits Your Product

Even if your product is already in the ideal type of container of the ideal thickness, you can still potentially reduce the costs by reducing the materials used. This would be done by opting for a size and shape of box that better fits your product. The less empty space, the less excess material used in the packaging. And the less stuffing or packing materials you need to use.

If you can’t find something that’s a good fit for your product, consider custom packaging. This is surprisingly affordable, and it tends to do a great job protecting your product from potential damage. It also helps you stand out from competitors.

Replace Filler with Custom Inserts

If you do decide to use a box that is larger than your product or you just need something in the container to cushion it, consider a custom insert instead of traditional void fillers. This tends to be more affordable in terms of materials. It can also weigh less, helping you keep shipping costs down.

Be a Minimalist

There are multiple ways to bring minimalism into your packaging to save money. If you have several layers on your packaging, consider whether all are really necessary. Or look to things like the design and printing. Can you reduce the number of colors to reduce the cost? Would it be worth the savings?

Find the Right Packaging Manufacturer

Don’t forget that the packaging manufacturer you choose will also affect your overall costs. You need to find a balance between cost-friendliness and quality. Don’t fall for excessively cheap packaging that seems too good to be true. It will leave your product unprotected, hurt your reputation, and likely cost you more in the long run with damaged or returned merchandise.

Conclusion

Look at your product packaging to see if you can reduce costs. Consider using a different type of packaging, thinner materials, or a more appropriate container size. Then, consider custom inserts instead of expensive filler materials and minimalism.